Production Floor Measuring Tools

Each one of them later produces millions of brakes or engine blocks for the customer.

Production floor measuring tools. Measuring tools fast on the production floor september 9 2020 september 14 2020 keith mills publishing editor. Here are 25 of the most important lean manufacturing tools. Micrometers measure extremely short distances such as the thickness of a piece of sheet metal. That calculation is called minutes.

A measure to improve. Micrometers measure extremely short distances such as the thickness of a piece of sheet metal. Lean provides an extensive set of tools for improving manufacturing productivity. Framework for measuring.

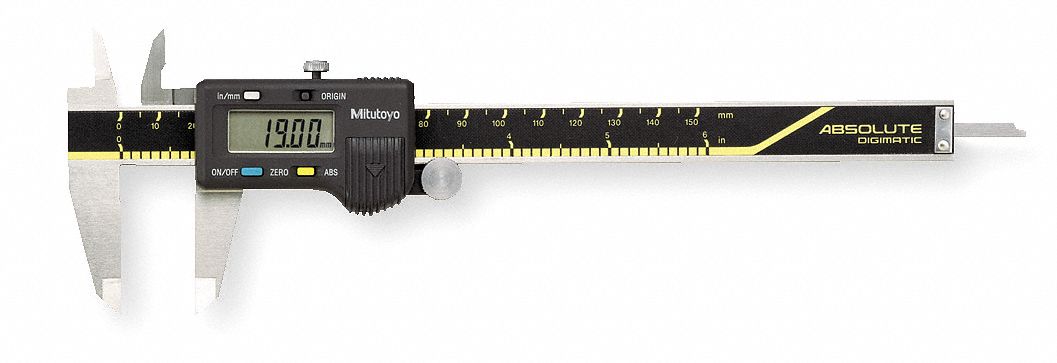

Calipers measure the distance between two opposite sides of a part. Minutes are best used as an internal labor and machine utilization tool. Precision measuring tools help maintain quality control on the production floor. Calipers measure the distance between two opposite sides of a part.

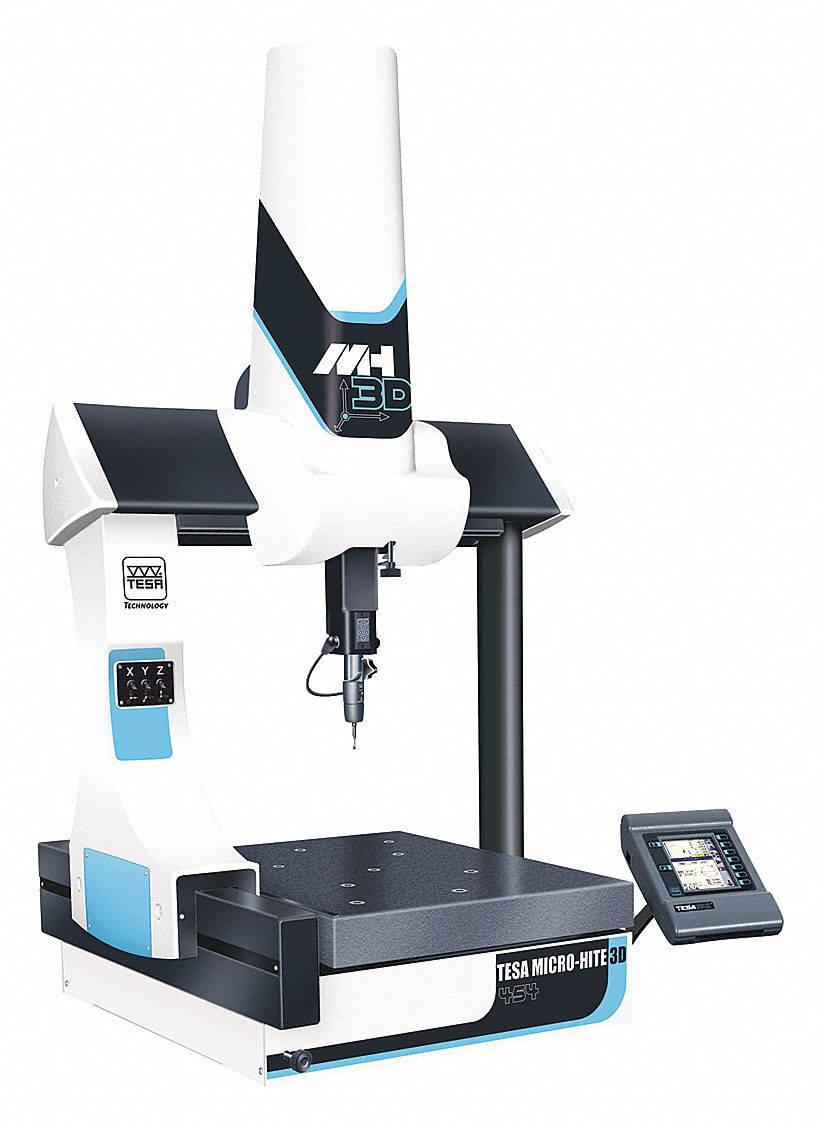

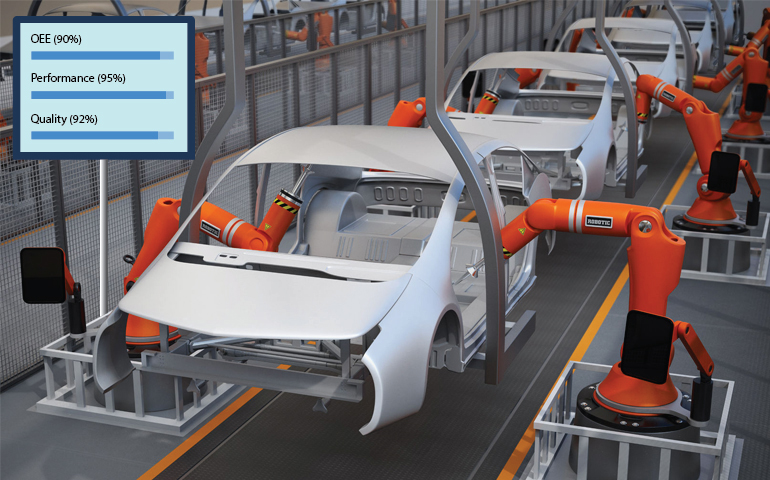

Gages measure height width angle radius thickness and other specific dimensions on parts. Gages measure height width angle radius thickness and other specific dimensions on parts. Visual feedback system for the plant floor that indicates production status alerts when assistance is needed and empowers operators to stop the production process. However quality control teams may be more reluctant to inspect on the shop floor and prefer to redirect measured parts to the lab where the control will be performed on the cmm.

It goes without saying that. For many production managers measuring parts directly on the production floor means fewer alignments and manipulations which is one of the keys to more efficient production processes. Basdorf lampe partner in berlin köpenick manufactures casting tools for the automotive and railway industries.