Process Of Making Natural Rubber

In this beginning stage pre heating takes place in the rubber forcing the rubber to flow through channels.

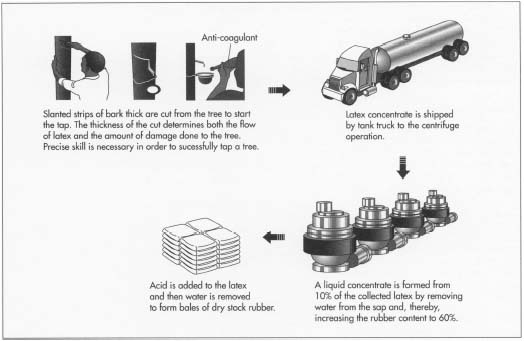

Process of making natural rubber. The process starts out with a blank being loaded in the chamber which is then distributed into several cavities. Transfer molding is a natural progression in development to limit the disadvantages of compression molding. International rubber study group. It takes several quite distinct steps to make a product out of natural rubber.

First you have to gather your latex from the rubber trees using a traditional process called rubber tapping. At approximately 2 321 per ton the natural rubber market involved about 22 5 billion in 2007 source. Rubber rubber processing. The rubber production process begins with natural or synthetic rubber.

Natural rubber comes from latex. That involves making a wide v shaped cut in the tree s bark. Processing natural rubber consists of the following steps. But before that natural rubber is transformed into stuff like hoses rubber bands and little yellow ducks it has to be processed.

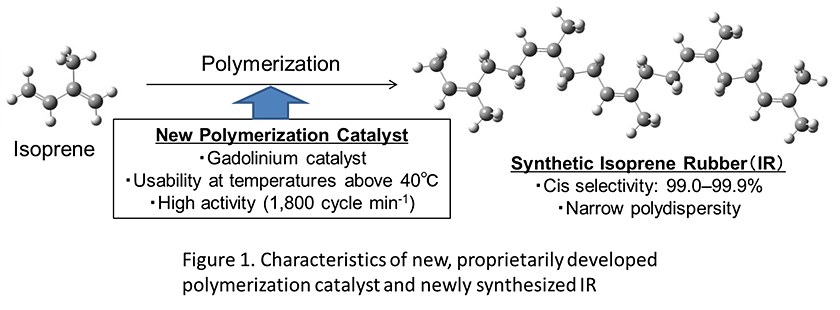

Synthetic rubber derives from molecular polymers. Compounding mixing molding and casting and finally vulcanization. Types of polyisoprene that are used as natural rubbers are classified as elastomers. Whether natural or synthetic rubber continues through four steps.

1 mastication when the elastomer is sheared and the molecules are broken down to give easier flow 2 mixing usually carried out immediately after mastication when additives are incorporated 3 shaping of the viscous mass for example by extrusion or molding and 4 curing when the polymer molecules become.