Porous Ceramic Properties

Advanced porous ceramics also called ceramic foams are being utilized in a broad range of applications in order to mitigate several environmental biological and transportation related issues facing society ceramic materials offer many distinct advantages over other materials such as polymers or metals.

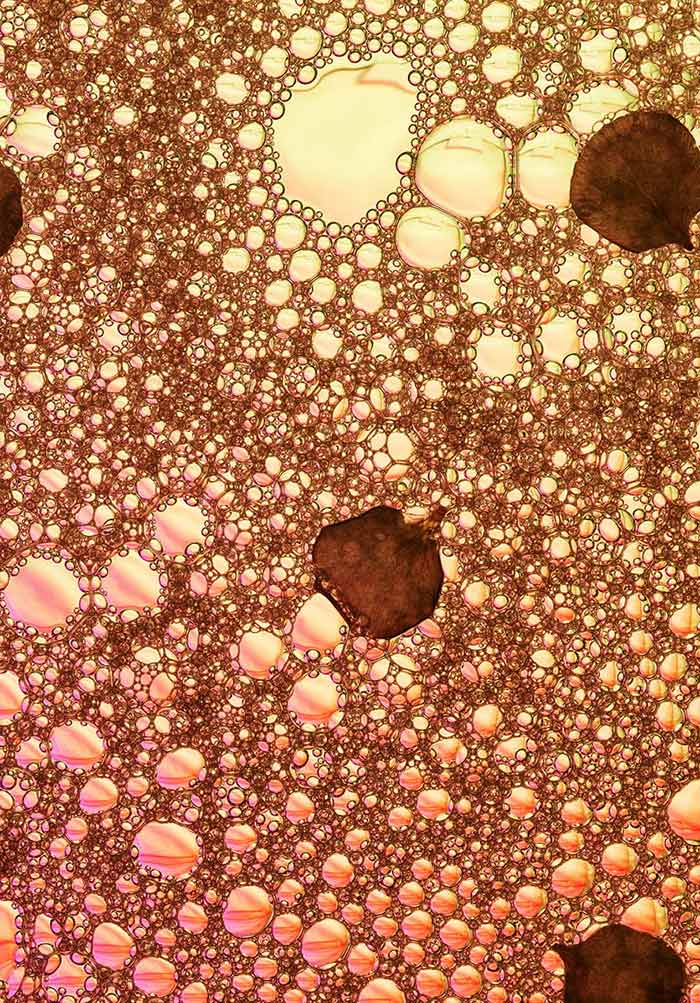

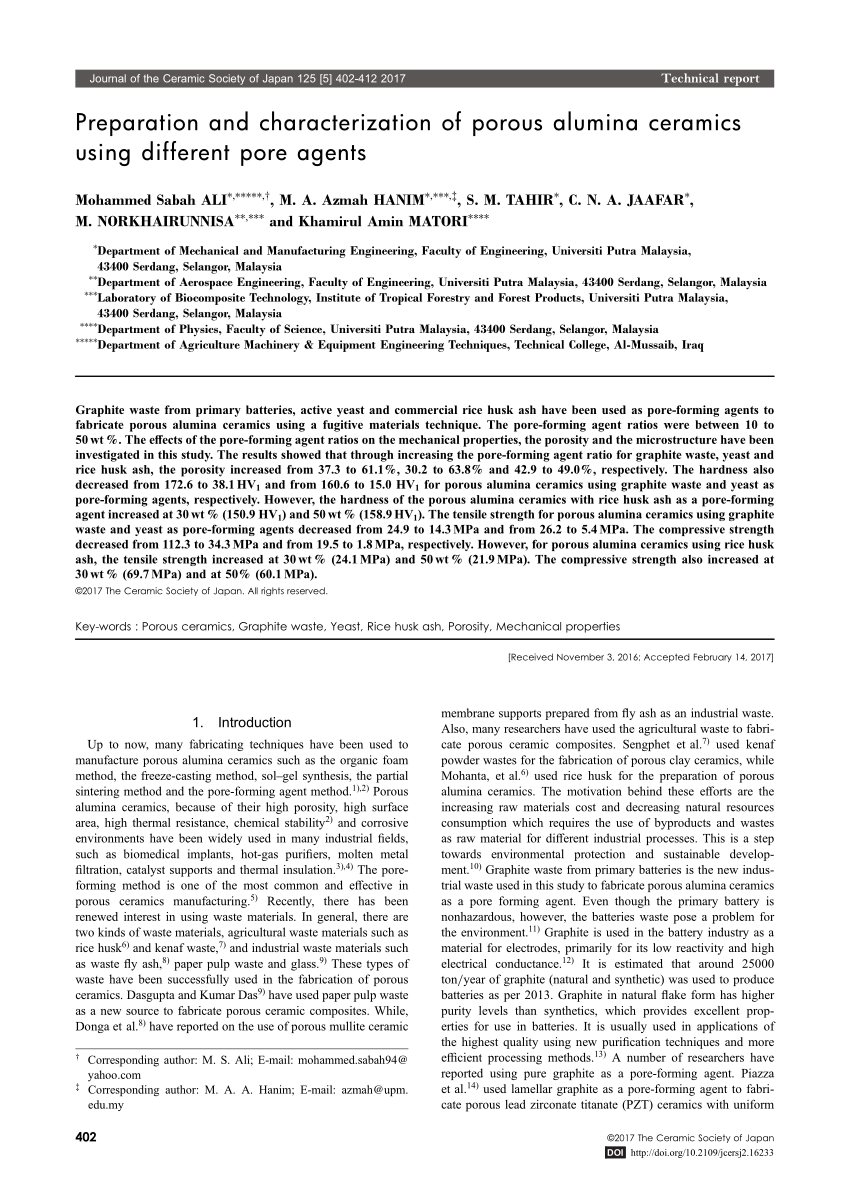

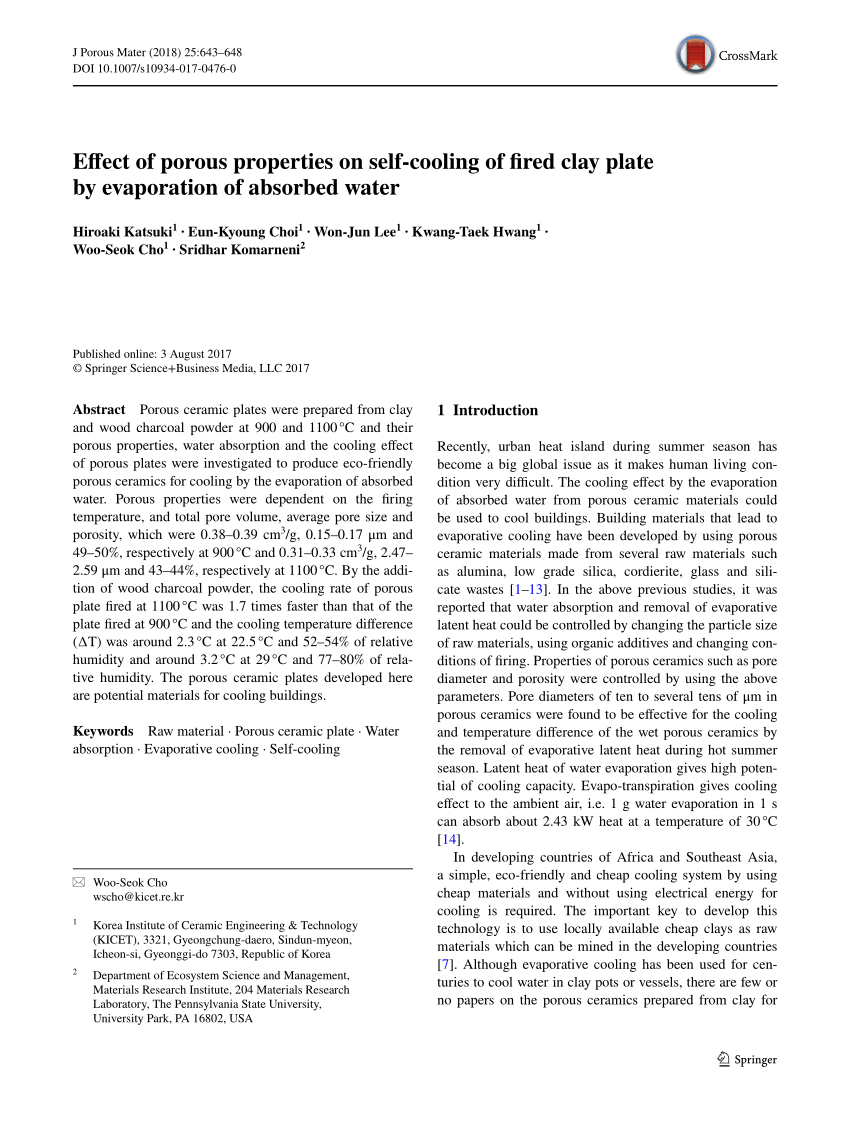

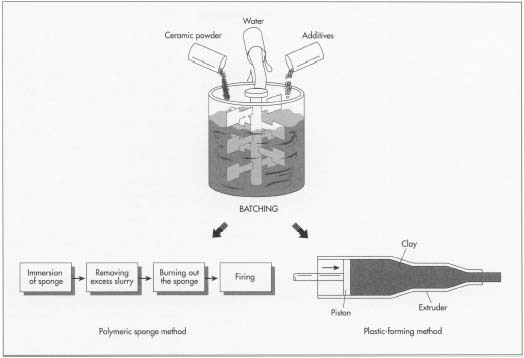

Porous ceramic properties. The aim of this chapter is to review the mechanical properties of macro porous ceramics. Porous ceramics have grown in importance in the industry recently because of their many applications like filters absorbers dust collectors thermal insulation hot gas collectors dielectric resonators bioreactors bone replacement and automobile engine components 1 2 3 4 generally porous ceramics have good properties such as mechanical strength abrasion resistance chemical and. The effects of material composition and process parameters on the properties of the prepared porous alumina ceramics were studied thoroughly. Appropriate ceramic catalyst carriers were prepared and characterised according to the requirements of mechanical properties surface acidity specific surface area and pore size distribution from real applications in the petrochemical industry.

The following issues are of particular interest to this paper. It is widely known that increasing interest in porous ceramics is due to their special properties which comprise high volumetric porosity up to 90 with open or closed pores and a broad range of pore sizes micropores. A ceramic material is an inorganic non metallic often crystalline oxide nitride or carbide material. They withstand chemical erosion that occurs in other materials subjected to acidic or caustic environments.

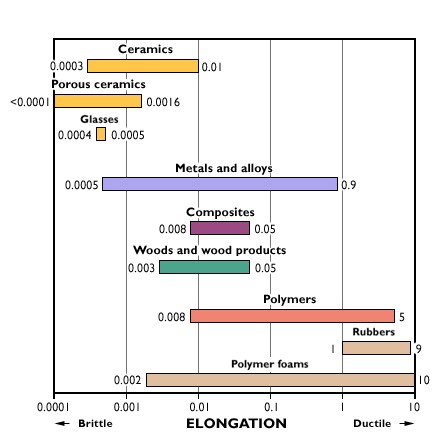

Some elements such as carbon or silicon may be considered ceramics ceramic materials are brittle hard strong in compression and weak in shearing and tension. 50 nm d 2 nm and macropores. These properties have many uses comprehending macroscaled devices mesoscaled materials and microscaled pieces.