Polymer Vs Ceramic Coated Screws

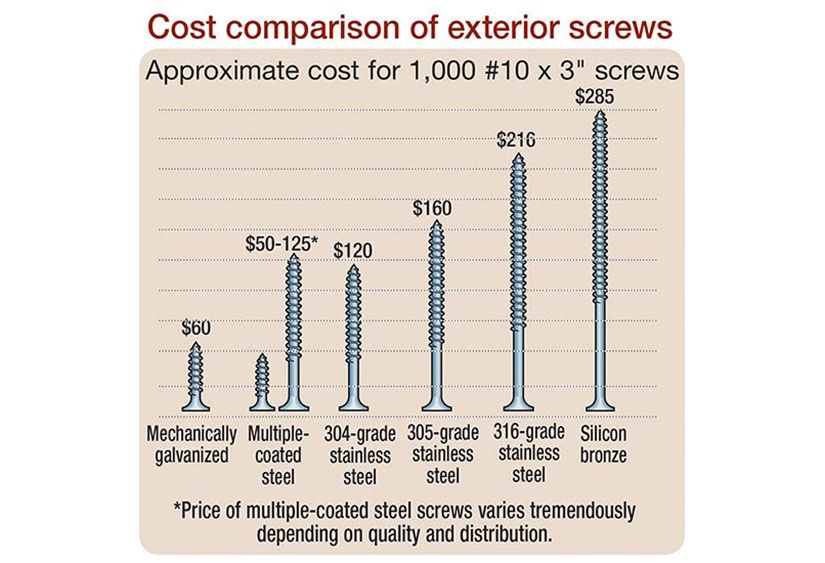

Screws made of this material may cost twice as much as coated steel fasteners.

Polymer vs ceramic coated screws. The screws provide long lasting performance and definitely it doesn t get damaged over time. A dacro plated fastener has a similar though not as corrosion resistant finish. Like the other screws it doesn t have any coating for the corrosion but corrosion cannot affect it. For instance titan metal werks a fastener manufacturer charges about 25 for 400 of their acq rated zinc coated with a polymer topcoat 6 by 2 inch splitstop screws.

But stainless steel is well worth it if you don t want to see any rust or stain marks on your project. As the name suggests the screw includes a thin polymer coating on the main metal of the screws. These are available in a wide variety of colors and the resin coating will not chip off as easily during installation as can be the case with ceramic. Recommended for use with acq ca and cca treated lumber plus cedar and redwood where they won t stain the wood.

Because of the high standard quality of the screws you can use it both indoor and outdoor also. Heated fasteners are tumbled through zinc powder or zinc chips which bond to the surface. The ceramic coated screws can be a great choice for the deck and other exterior application. The green ceramic coating provides superior rust and corrosion resistance with 4 layers of protection a zinc layer a chemical adhesion layer an epoxy coating and a durable protective finish.

Ceramic coated screws can be used with both pressure treated lumber and composite decking. Whenever you put time or expensive lumber into a clear finished project it doesn t make sense to use anything but stainless steel. Any manufacturer s stainless steel products will cost more than its coated steel ones. Electroplating is used to coat nails and screws with a thin layer of zinc.

Weather maxx bronze ceramic coat. Engineered using star drive technology these screws are twice as durable as a phillips drive and prevent stripping. Power pro brand screws with multiple layers of zinc and polymer based coatings. The polymer coating acts like a plastic wrapper to keep water and dissolved copper from reaching and reacting with the zinc and steel.

Screws are coated with a thin layer of epoxy or ceramic. In contrast the same size and number of stainless screws costs about 66. The polymer coated deck screws are becoming extremely popular as they offer versatile protection against the rust and corrosion. Polymer coated steel screws nails and bolts rely on a thin zinc plating covered with a non reactive organic polymer coating to fight corrosion in copper treated wood.