Polycarbonate Laminated Printing

Simplify3d also includes a useful option called coasting which will automatically reduce the.

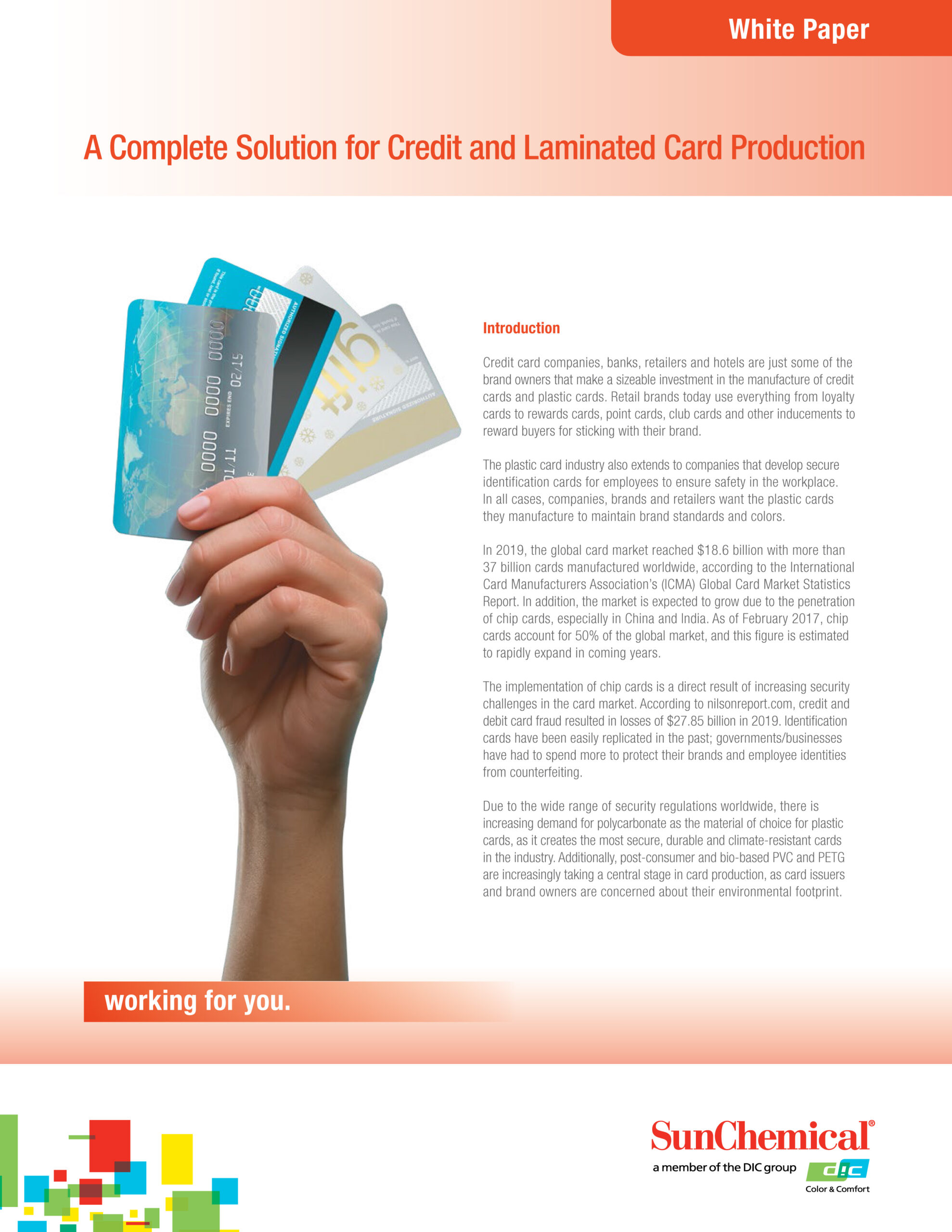

Polycarbonate laminated printing. Printing is laminated to protect it from stains and moisture to increase its strength and durability and to add sheen. Teslin substrate can be combined with polycarbonate pc to produce multi component credentials that incorporate the best security features of both substrates including lamination strength color photography laser engraving embedded covert and forensic security markers and long term protection of embedded electronics. Laminated printing refers to printed pieces that have been enclosed between two sheets of clear plastic film. To prevent this try increasing the retraction distance and retraction speed.

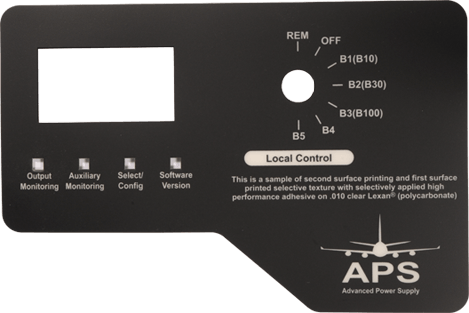

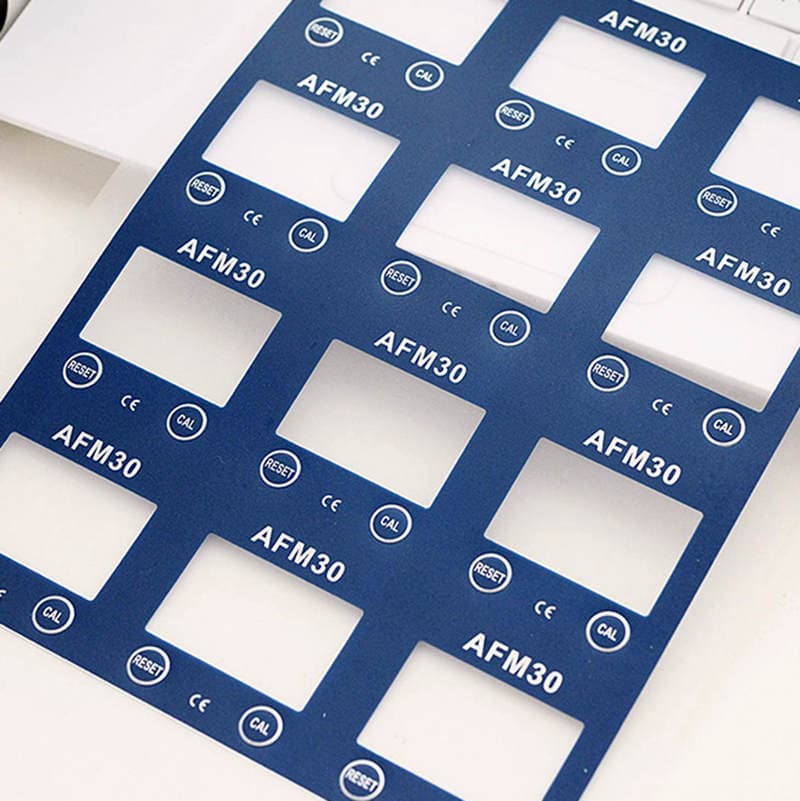

Description 5 0 mil velvet polycarbonate overlaminating film. Lexan nameplate labels are the perfect fit for applications that take a lot of wear and tear due to extreme temperatures harsh weather conditions making them both functional attractive. Lml6500 polycarbonate velvet laminate. Use this product is designed for use as a protective overlaminate where graphics may experience a high exposure to scuffing this laminate adds depth to the aesthetics of visual images such as photo displays and point of purchase graphics.

Outdoor life of laminating film is one year. A high temperature heated bed is necessary for printing with polycarbonate. Lexan polycarbonate laminate is a preferred material when it comes to durable nameplate and label applications. As far as printing temperatures go you need a 3d printer with a hot end that can reach and maintain a minimum of 290 c.