Polar Vinyl Polymers

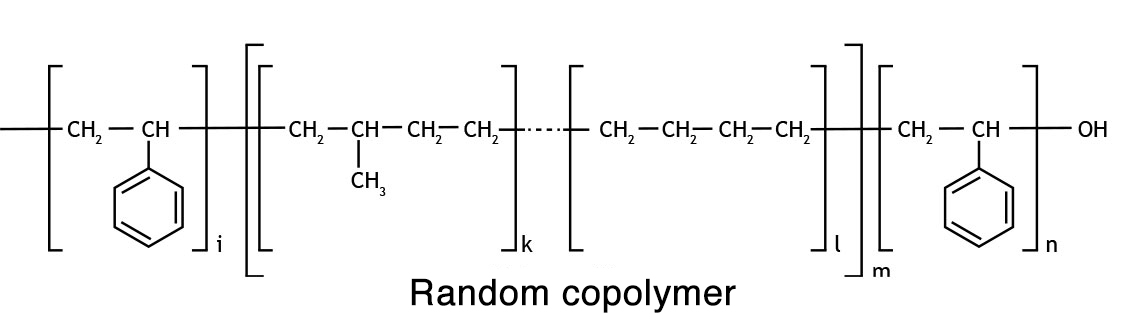

The polymerization of polar vinyl monomers in the presence of lewis acids produces stereoregular vinyl polymers.

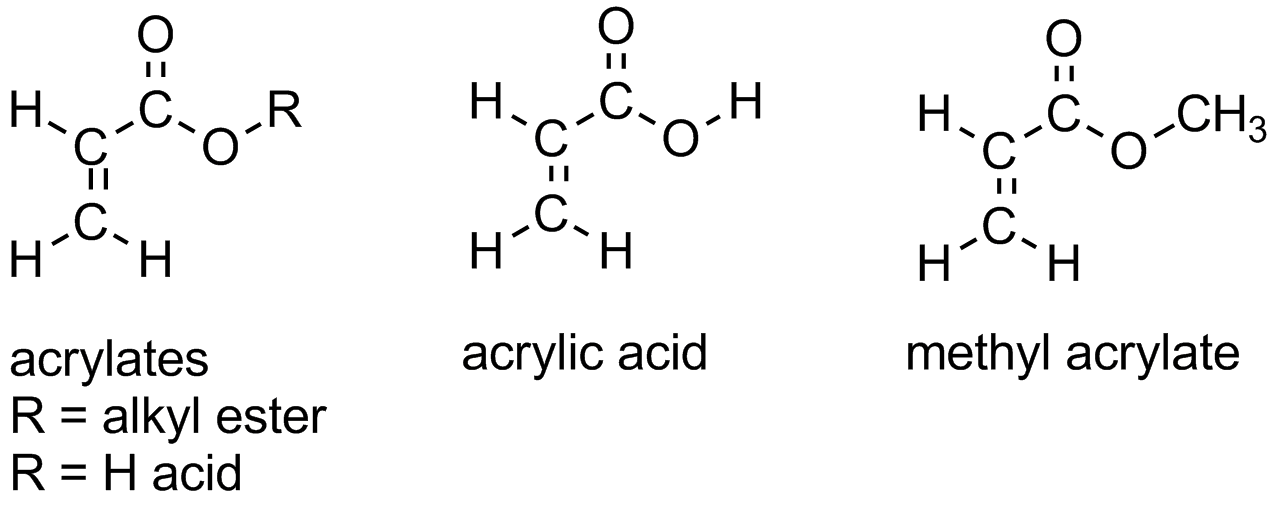

Polar vinyl polymers. Their low polarity prevents them from bonding well to filler surfaces. Nerurkar chemistry department west ham college of technology london e 15 received 12 march 1968 abstract the development of crystallinity in polyvinyl alcohol films prepared by controlled evapora tion of aqueous solutions has been studied. This review highlights the challenges associated with conventional polymerization systems and evaluates the most relevant methods which have been developed to bridge the gap between polar vinyl monomers and olefins. The mixtures or monomer lewis acid complexes may be polymerized to produce the desire stereoregular vinyl polymers.

The printable vinyl has a very high opacity giving it a consistent printing surface with sharp colours and bright whites. Research over the past 20 years has greatly advanced the copolymerization of polar vinyl monomers and olefins. More polar polymers for example nylons 6 and 6 6 are able to interact well with fillers even in the absence of coupling agents. With both permanent and removable adhesive options polar polymeric self adhesive vinyl maximises adhesive performance and durability on a wide variety of substrates.

The permanent version has a lifespan of over three years while the removable version is recommended for short term applications. Crystallization in films of polar vinyl polymers i. This review highlights the challenges associated with conventional polymerization systems and evaluates the most relevant methods which have been developed to bridge the gap between polar vinyl monomers and olefins. Crystallinity of polyvinyl alcohol films prepared by evaporation of aqueous solutions a.