Point To Ground Method Esd Flooring Checking

The samples should be numbered from 1 to 5.

Point to ground method esd flooring checking. Learn more about desco s digital surface resistance meter kit here. The standard governing workstations is ansi esd 6 1. Scope this test method covers the determination of electrical conductance or resistance of resilient flooring either in tile or sheet form for applications such as hospitals computer rooms clean rooms access flooring munition plants or any other environment concerning personnel generated static electricity. The three most widely used procedures are described below.

The paint will absorb the static charge but it needs somewhere to escape via a grounding point. Many of the test methods ansi esd stm7 1 and astm f150 are developed to report the characterization of esd floor materials and more importantly their performance in combination with a person wearing. All five samples must be conditioned for the full 72 hours at low humidity. The third party measured electrical resistance per esda standard test method ansi esd stm 7 1.

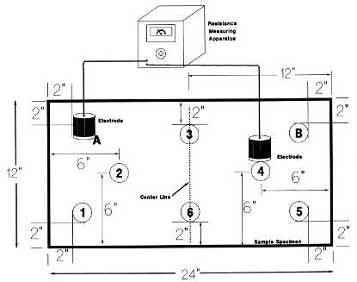

The purpose of painting your floor with esd paint is to remove static. Resistance to ground testing rtg to qualify a flooring product you will need five 12 x 24 samples with two groundable points per sample. Only use electrical receptacles outlets that have been previously tested using an approved circuit tester complying with csa and or ul standards. Tests included point to point rtt and point to ground rtg measurements.

The desco digital surface resistance meter kit measures resistance point to point rtt or surface to ground rtg of worksurfaces flooring systems garments and other materials in accordance with esd association documents. Grounding cables end in eyelets so that you can tie them into the outlet. Grounding conductive and static dissipative tile and sheet flooring to an ac electrical outlet is the easiest and most common grounding method. There are several esd floor test methods associated with and recommended by voluntary associations with a keen focus on the phenomenon and control of static electricity in work environments.

Grounding esd static control flooring several acceptable methods are used to ground static control flooring depending on local codes the job conditions and the personal preference of the contractor. To ground anti static mats we insert a conductive snap on the corner of the anti static mat. If an anti static mat is isolated from electrical ground by insulators carpets painted floors or tables you need to connect it to an electrical outlet by using a grounding cable. Affixing the copper grounding strap to the floor tile or static control floor coating.

Grounding is a simple easy process. Each sample will be tested 6 times from both ground points per the diagram below. Esd tr53 ansi esd s4 1 ansi esd s7 1 ansi esd stm97 1 and other documents. You should connect all grounded people and equipment to an electrical outlet electrical outlets follow the piping to the earth underneath building.

The snap is where you will connect the grounding cable. It covers the range of ways that wrist straps personnel and mats can be electrically bonded grounded.

%2C445%2C291%2C400%2C400%2Carial%2C12%2C4%2C0%2C0%2C5_SCLZZZZZZZ_.jpg)